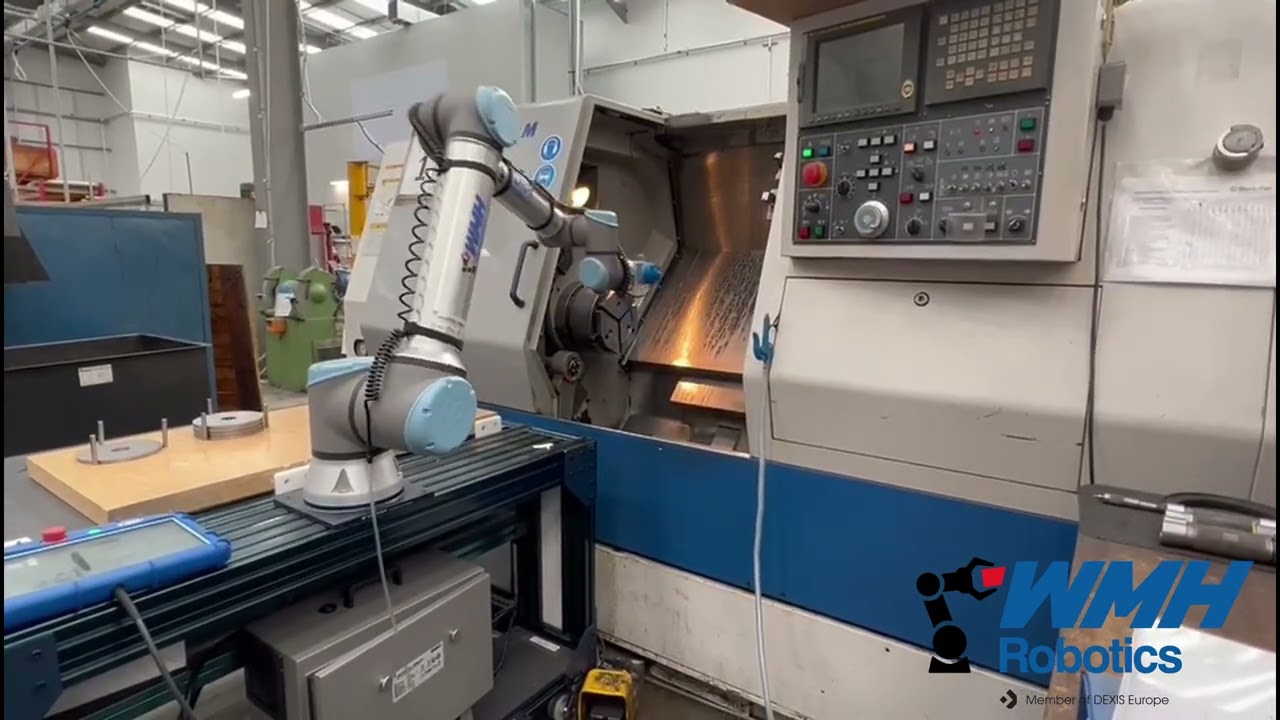

WMH Robotics offer a unique machine tending solution by combining off the shelf components to give you advanced systems for a fraction of the cost!

By enabling self-deployment we dramatically reduce cost (by up to 60%) and reduce lead times meaning you spend more time producing!

Cobot Machine tending stands alone in the market as its own unique solution. It provides manufacturers with a small footprint, flexible, short lead time and cost-effective tending solutions:

Benefits of UR TEND:

-

Works by using off-the-shelf components and customised frameworks

-

Low Cost & Short Lead-Times

-

ROI is typically under 12 months

-

Small footprint - No Guarding - Flexible Deployment

-

CNC signal integration is possible for 80% of machines

-

We offer comprehensive on-site training to help you start producing quickly

Get in touch to discuss your Machine Tending requirement:

Typical Cell Specifications

- Part Weight

- 0-25kg per part - Single Pick

- 0-12Kg per part - Dual Pick

- Robot Reach

- 900-1,750mm Reach available

- Gripping technology

- 2 & 3 Finger grippers

- Vacuum Grippers

- Magnetic grippers

- Dual-Grippers

- Machine integration

- Out-of-the-box deployment for most machine tools

FlexxCNC™: UR to CNC Communication Interface

Part 1 - Connect your cobot and machine to the FlexxCNC™ middleware

Part 2 -Wire to your peripherals

- Dedicated & labeled I/O

- Wiring kits & instructions to all peripherals

Part 3 -Build your program

- Upload the executable/configure server connection

- Build your program in polyscope using Flexx programming nodes

Machine Tending Cell Videos:

How can we help?